Clean-Room Microfiber Wipes

Clean-Room Microfiber Wipes Specification

- Product Type

- Clean-Room Microfiber Wipes

- Material

- 75% Polyester, 25% Nylon Microfiber

- Application

- Clean-room, Electronics, Semiconductor, Laboratory

- Surface Resistance

- 10^6 - 10^9 ohms/sq

- Usage

- Single Use or Reusable

- Testing Function

- Lint Free, Non-abrasive Cleaning

- Trigger Mode

- Manual

- Detection Method

- Visual and Surface Particle Inspection

- Size

- 9 x 9 inches (other sizes available)

- Dimension (L*W*H)

- 9 x 9 inches x 1 mm (per wipe)

- Weight

- ~0.5g (per wipe)

- Color

- White

- Packaging

- 100 wipes per bag, double-bagged for cleanroom entry

- Sterilization

- Can be autoclaved or gamma sterilized

- Edges

- Laser cut or ultrasonic sealed edges for reduced fiber contamination

- Reusable

- Disposable, single use

- Particle Generation

- Ultra-low particle generating

- Shelf Life

- Up to 2 years when stored properly

- Cleanroom Compatibility

- ISO Class 3-5 (Class 1-100)

- Absorbency

- High, suitable for solvents and liquids

About Clean-Room Microfiber Wipes

Clean-Room Microfiber Wipes are ultra-soft, lint-free wipes made from a blend of polyester and polyamide fibers, specifically designed for use in cleanroom environments. They offer excellent cleaning capabilities, effectively trapping dust, dirt, and contaminants without scratching surfaces. Highly absorbent and durable, these wipes are ideal for cleaning sensitive equipment and surfaces in industries such as electronics, pharmaceuticals, and biotechnology. Their low particle generation helps maintain strict contamination control, making them essential for ensuring cleanliness in controlled environments.

Precision Engineered for Cleanrooms

Clean-Room Microfiber Wipes are manufactured to meet the demanding standards of ISO Class 3-5 controlled environments. With laser-cut or ultrasonic-sealed edges, they drastically reduce the risk of fiber shedding, making them ideal for tasks that require ultra-low particle generation and clean surfaces. Each wipe delivers consistent, reliable cleaning for high-sensitivity applications.

Exceptional Absorbency and Compatibility

Their advanced microfiber blend absorbs both solvents and liquid spills rapidly, while their structure remains non-abrasive against sensitive surfaces. Suitable for use in sophisticated industries such as semiconductors and advanced laboratories, these wipes deliver spotless results and lint-free finishes, ensuring equipment and environments remain particle-free.

FAQs of Clean-Room Microfiber Wipes:

Q: How are Clean-Room Microfiber Wipes sterilized before use?

A: Clean-Room Microfiber Wipes can be sterilized using either autoclaving or gamma irradiation. This flexibility ensures they meet varied sterilization protocols across different industries and enhance contamination control.Q: What makes these wipes suitable for cleanroom environments?

A: Their ultra-low particle generation, laser-cut or ultrasonic-sealed edges, and double-bagged packaging make them ideal for ISO Class 3-5 cleanrooms. They help maintain clean surfaces without introducing lint or fibers.Q: When should I use these wipes in my facility?

A: These wipes are suitable for any application requiring cleanliness and low particle contamination, such as during equipment maintenance, surface preparation, or cleaning spills in electronics manufacturing and laboratory settings.Q: Where can these wipes be applied most effectively?

A: They are best used in clean-forced environments like electronics plants, semiconductor labs, and research facilities, where even minimal contamination could affect product quality or outcomes.Q: What are the benefits of single-use, disposable wipes for cleanrooms?

A: Single-use wipes reduce the risk of cross-contamination and guarantee a fresh, uncontaminated cloth for each cleaning task, safeguarding the integrity of your cleanroom process.Q: How do the edges prevent fiber contamination?

A: The wipes feature precision laser-cut or ultrasonic-sealed edges that greatly minimize fiber or particle release, ensuring superior cleanliness during wiping and reducing contamination risks.Q: What is the shelf life and proper storage method for these wipes?

A: When stored in unopened, clean, dry environments, these wipes can maintain their performance for up to two years, making them cost-effective and reliable for long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ESD cleanroom consumables Category

Cleanroom Foam Swab

Price 10.0 INR / Pack

Minimum Order Quantity : 500 Packs

Weight : 200 Grams (g)

Application : clean room

Color : WHITE

Product Type : esd

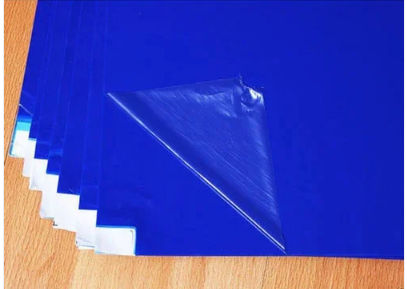

Esd Sticky Mats

Price 220.0 INR

Minimum Order Quantity : 10

Weight : 1 Kilograms (kg)

Application : Laboratory

Color : Blue

Product Type : Cleanroom

Clean-Room Cellulose Wipes

Price 450.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Weight : 55 GSM (gm/2)

Application : Clean Room Environment

Color : White

Product Type : PBSSCleanroom Wipes Nonwoven Wipes Cellulose/Polyester Blend (Grade A, 68 Gram) 9 x 9 (Bag of 500 Pcs) for Lab

SS Industrial Air Shower

Price 195000.0 INR

Minimum Order Quantity : 1

Weight : 350 Kilograms (kg)

Application : N/A

Color : silver

Product Type : Air Shower

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS