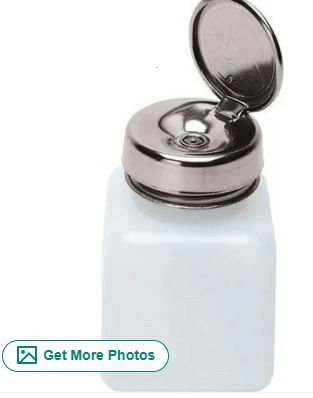

ESD Dispenser Bottles

ESD Dispenser Bottles Specification

- Product Type

- ESD Dispenser Bottle

- Material

- Conductive Polyethylene

- Application

- Dispensing cleaning solutions, solvents, and chemicals in ESD safe environments

- Surface Resistance

- 10^5 to 10^9 Ohms

- Usage

- Static control dispensing in electronics manufacturing, labs, repair workstations

- Output Voltage

- <50V

- Testing Function

- Prevents electrostatic discharge

- Trigger Mode

- Push-down pump

- Detection Method

- Surface resistance testing

- Size

- Available in 180 ml, 250 ml, 500 ml, 1 Liter sizes

- Dimension (L*W*H)

- Varies by capacity, approx. 60mm x 60mm x 160mm for 250 ml

- Weight

- Approx. 80g (empty, 250 ml)

- Color

- Black

- Cleanroom Compatibility

- ISO Class 5-8 recommended

- Cap Type

- One-touch pump with stainless steel spring

- Lid Material

- Conductive polypropylene

- Heat Resistance

- Temperature tolerant up to 70°C

- Bottle Markings

- Graduated scale for liquid measurement

- Seal Type

- Leak-proof, tight-seal lid

- Reusability

- Reusable and easy to refill

- Flame Retardant

- No

- Chemical Compatibility

- Compatible with most industrial solvents and alcohols

- RoHS Compliance

- Yes

- Static Dissipation Time

- Less than 2 seconds

About ESD Dispenser Bottles

ESD Dispenser Bottles are specialized containers designed for the safe storage and dispensing of liquids in electrostatic discharge (ESD) sensitive environments. Constructed from anti-static materials, these bottles prevent the buildup of static electricity, reducing the risk of electrostatic discharge that can damage sensitive electronic components. The bottles typically feature a precision dispensing nozzle for controlled application, making them ideal for use with solvents, cleaning agents, and other chemicals. Lightweight and easy to handle, ESD dispenser bottles are essential for maintaining safety and compliance in industries such as electronics manufacturing, cleanrooms, and laboratories.

Enhanced ESD Protection for Critical Applications

These dispenser bottles safeguard your sensitive workspaces by preventing static build-up that could damage electronic components. Their conductive polypropylene lids and conductive polyethylene construction maintain output voltages below 50V, ensuring compliance with electronics manufacturing standards. With surface resistance measured at 10^5 to 10^9 Ohms, they reliably dissipate static within 2 seconds, making them ideal for repair, assembly, and lab environments.

Practical, Durable, and Leak-Proof Design

Designed for convenience and precision, the bottles feature a one-touch pump mechanism and a graduated scale for accurate dispensing. The tightly sealed lids ensure leak-proof storage and easy portability, while heat resistance up to 70C accommodates demanding industrial applications. Reusable and easy to refill, these bottles are available in various sizes to accommodate different needs in any workspace.

FAQs of ESD Dispenser Bottles:

Q: How do the ESD dispenser bottles prevent electrostatic discharge during use?

A: These bottles are made from conductive polyethylene with a conductive polypropylene lid and a stainless steel spring, providing a safe path for static to dissipate. Their surface resistance (10^5 to 10^9 Ohms) ensures electrostatic charges are neutralized in under two seconds, keeping electronic components protected during liquid dispensing.Q: What types of liquids are compatible with these dispenser bottles?

A: They are designed to dispense a wide range of industrial solvents and alcohols that are commonly used in electronics manufacturing, laboratories, and repair workstations. The materials used can handle most chemicals except those requiring flame-retardant containers.Q: When should these dispenser bottles be used in a cleanroom environment?

A: These bottles are recommended for use in cleanroom environments with ISO Class 5-8 ratings. Their construction and static control properties help maintain stringent contamination and ESD controls necessary for high-tech assembly and laboratory processes.Q: Where are these ESD dispenser bottles typically applied?

A: They are widely used on ESD-safe workbenches in electronics manufacturing sites, laboratories, and repair facilities. Ideal for dispensing controlled quantities of cleaning solutions and solvents, they support safe handling near static-sensitive equipment.Q: What process should I follow to refill and maintain these bottles?

A: To refill, simply unscrew the leak-proof cap and fill the bottle with the desired solution. Regularly clean the bottle with a compatible solvent to ensure longevity and maintain the integrity of the conductive properties. Always reseal tightly after refilling to prevent leaks.Q: What are the benefits of using graduated scale bottles with tight-seal lids?

A: The graduated scale provides precise liquid measurement, aiding in accurate solution preparation and waste reduction. The tight-seal, leak-proof lid ensures safe storage and minimizes spills, providing convenience and reliability across applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ESD Safe Products Category

ESD Common Grounding 2 Pin Point

Price 110.0 INR

Minimum Order Quantity : 10

Product Type : safe product

Color : balck

Weight : 75 Grams (g)

Size : N/A

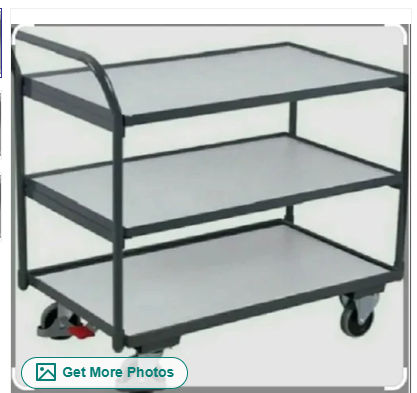

ESD SAFE TROLLEY

Price 19500.0 INR

Minimum Order Quantity : 1

Product Type : esd

Color : silver

Weight : 15 Kilograms (kg)

Size : 120 inch or more

Anti Static Esd Rope

Price 450.0 INR

Minimum Order Quantity : 500

Product Type : ESD Material Storage Handling & Packaging Aids

Color : wite

Weight : 1.5 Kilograms (kg)

ESD Common Grounding 4 Pin Point

Price 195.0 INR

Minimum Order Quantity : 10

Product Type : ESD Common Grounding 4 Pin Point

Color : Black/Yellow

Weight : 45 g

Size : Compact

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS