ESD Conductive Wheel

ESD Conductive Wheel Specification

- Product Type

- ESD Conductive Wheel

- Material

- High Strength Thermoplastic Elastomer with Conductive Additives

- Application

- ESD-Safe Trolleys, Carts, Material Handling Equipment in Electronic Manufacturing

- Surface Resistance

- 10^4 - 10^6

- Usage

- Safe ground mobility and protection against electrostatic discharge

- Output Voltage

- N/A (Passive Component)

- Testing Function

- Surface Resistance Tested for ESD Compliance

- Trigger Mode

- Passive

- Detection Method

- Electrostatic Surface Resistance Measurement

- Size

- 100 mm (Diameter)

- Dimension (L*W*H)

- 100 x 30 x 35 mm

- Weight

- 0.16 kg

- Color

- Black

- Compliance

- RoHS and REACH compliant

- Chemical Resistance

- Resistant to common cleaning agents and solvents

- Mounting Type

- Plate or bolt hole

- Hardness

- 85±5 Shore A

- Temperature Range

- -20°C to +60°C

- Load Capacity

- Up to 120kg per wheel

- Bearing Type

- Double ball bearing

- Maintenance

- Maintenance-free design

- Corrosion Resistance

- High

- Non-marking

- Yes

ESD Conductive Wheel Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- no

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 2000 Pieces Per Month

- Delivery Time

- 4 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About ESD Conductive Wheel

An ESD Conductive Wheel is a specialized wheel designed for use in environments where static electricity control is essential. Constructed from conductive materials, these wheels help dissipate electrostatic charges, preventing the accumulation of static electricity that can damage sensitive electronic components. Ideal for use on carts, equipment, and workstations in ESD-safe areas, these wheels ensure smooth mobility while maintaining compliance with industry standards for static control. Their durable design makes them suitable for various applications, including electronics manufacturing, cleanrooms, and laboratory settings.

Superior ESD Protection for Sensitive Environments

Designed for use in ESD-safe trolleys and carts, this wheel reliably dissipates electrostatic charges, safeguarding delicate electronic components from damage during transit. Its conductive material and certified surface resistance deliver trustworthy protection in high-tech manufacturing spaces.

Durable and Maintenance-Free Performance

Constructed with a robust thermoplastic elastomer and double ball bearings, the wheel excels in both load-bearing and longevity. Its maintenance-free design and resistance to corrosion, solvents, and common cleaning agents make it ideal for routine operations in industrial and cleanroom settings.

Versatile and Easy to Install

Available with both plate and bolt hole mounting options, this 100 mm diameter wheel seamlessly fits standard equipment. Its non-marking black surface protects floors while delivering stability and smoothness within a temperature range of -20C to +60C.

FAQs of ESD Conductive Wheel:

Q: How does the ESD Conductive Wheel protect electronic components during handling?

A: The wheel is formulated with conductive additives to provide a certified surface resistance of 10^410^6 , enabling it to safely dissipate static electricity and prevent electrostatic discharge that could damage sensitive electronic devices during transportation.Q: What materials are used in the construction of the wheel and why?

A: The wheel is made from high-strength thermoplastic elastomer blended with conductive additives, chosen for their durability, flexibility, and ability to reliably conduct charges. This ensures both longevity and effective ESD protection under industrial conditions.Q: When should you use this wheel in your facility?

A: This wheel is ideal for use whenever transporting ESD-sensitive materials or components, particularly in electronic manufacturing and assembly environments where static control is crucial to product safety and quality assurance.Q: Where can the ESD Conductive Wheel be installed?

A: It is designed for versatile mountingeither plate or bolt holemaking it compatible with a broad range of material handling equipment, trolleys, and carts commonly used in ESD-controlled areas.Q: What is the process for verifying ESD compliance of the wheel?

A: Each wheel undergoes surface resistance testing using electrostatic measurement methods to ensure compliance with ESD safety standards, as mandated by RoHS and REACH directives.Q: How does the non-marking and corrosion-resistant feature offer operational benefits?

A: The non-marking design keeps floors clean and unmarred, while the high corrosion and chemical resistance allow the wheel to be used in environments with exposure to cleaning agents, solvents, or moisture, reducing equipment maintenance and downtime.Q: What are the advantages of choosing a maintenance-free wheel for industrial use?

A: A maintenance-free wheel streamlines operations by eliminating lubrication needs or frequent servicing, thus reducing labor costs and ensuring consistent, smooth mobility over its lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ESD Safe Products Category

Machine Sticky Roller

Price 1950.0 INR

Minimum Order Quantity : 1 Piece

Color : White : Blue, White

Product Type : Machine Sticky Roller

Weight : 200 Grams (g)

Usage : Clean

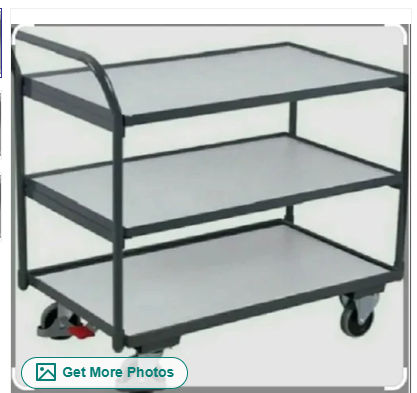

ESD SAFE TROLLEY

Price 19500.0 INR

Minimum Order Quantity : 1

Color : silver

Product Type : esd

Weight : 15 Kilograms (kg)

Usage : Electronic

Esd Floor Mat

Price 85.0 INR

Minimum Order Quantity : 10000

Color : green

Product Type : ESD Safe Products

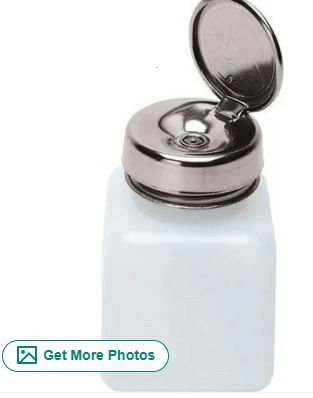

ESD Dispenser Bottles

Price 110.0 INR

Minimum Order Quantity : 10

Color : Black

Product Type : ESD Dispenser Bottle

Weight : Approx. 80g (empty, 250 ml)

Usage : Static control dispensing in electronics manufacturing, labs, repair workstations

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS